Our latest research is looking at vibration and how it impacts cycling wheels, rolling resistance, and most recently, the cyclist.

What know that vibration in a human creates micro tears in the muscles and the body attempts to stabilize itself, both leading to fatigue.

Our theory states that if you can manage the vibration through wheel design and optimal tire pressure, you can reduce fatigue in the cyclist. A reduction in fatigue would result in a faster ride and the potential to eliminate pain.

For this study, we worked with our friend, Dr. John Mercer, to try and capture the vibration experienced by the cyclist.

Vibration in Cyclists Testing Protocol

- Mount vibration sensors (3D accelerometers) to the fork of the bike and the forearm of the rider.

- Set a tire pressure range for testing to show a vibration profile in the wheel and human.

- Run the test on two bikes with two riders with different wheels and tires. John and I each rode a bike. John’s bike had FLO 77 AS wheels with 28mm Continental GP 5000 tires. My bike had FLO G700s with 37mm WTB Riddler tires.

Theory vs. Results

If I’m being honest, I thought this would be a lot easier than it’s turned out to be. I believed that as tire pressure dropped there would be a reduction of vibration in the fork and forearm. As with all things vibration, the results are more like reading tea leaves at the moment.

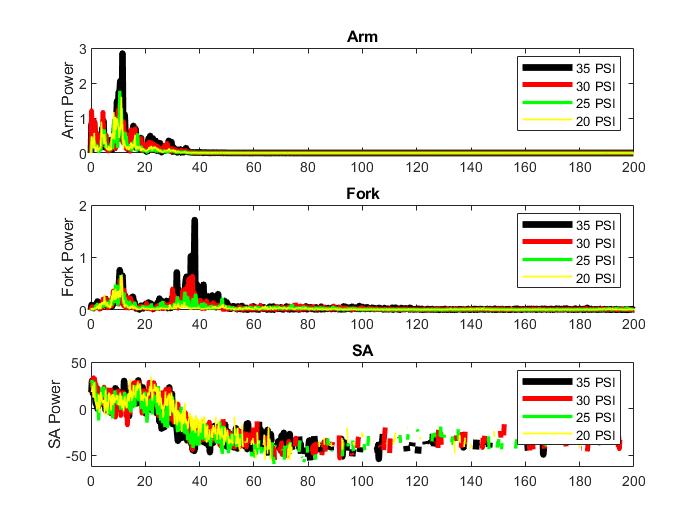

The image below shows three graphs. The top graph is a graph of the average power on the forearm for different tire pressures. The average comes from analyzing 5-second readings of vibration. You can see that the vibration profile is primarily under 25Hz. The second graph is the fork and the final graph is the signal attenuation. To get the signal attention (SA), you divide the forearm power by the fork power. What’s odd is there is an amplification from 0-25Hz. You can see this since the SA value is greater than one, which I did not expect.

You can see that as the tire pressure decreased the overall power drops. This was expected but the amplification is something we need to dig further into.

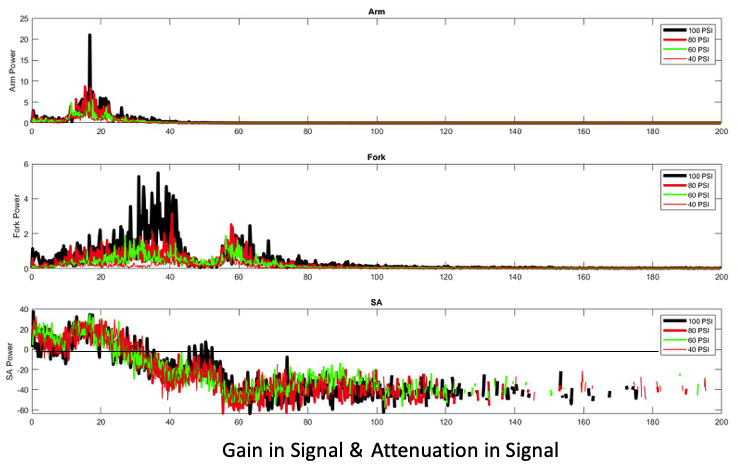

Here is the second graph. While the vibration profiles are different the overall result is the same.

Next Steps

The next steps are to mount more sensors on the bike and rider to see if we can find more of a pattern. We considered several things that could be causing the amplification like sway and cadence but these are very low frequencies so our initial guess is that it is something else. Stay tuned for the next study. If you want to check out any of our previous vibration work you can see the links below.

Related Articles

Using Tire Pressure to Measure Impedance

Natural Frequency in Cycling Wheels and Tires

Measuring Vibration in Cycling Wheels

Vibration on a Cycling Roller Trainer

Measuring Wheel Vibration with Different Speeds

Co-founder at FLO Cycling. Jon manages the day to day operations and acts as the lead engineer for all FLO products.