If you’ve ever owned a disc wheel, you will know that the only part of the wheel that is not covered, is the valve cutout. We are often asked if covering this valve cutout will improve aerodynamics. To be honest, we didn’t know the answer, so we studied it.

If you are interested in our other studies from the A2 Wind Tunnel, please be sure to check them out.

Does Tire Pressure Change Aerodynamic Drag?

Aerodynamic Difference between Sapim CX-Ray and Round Spokes

How Much Drag Does a Clydesdale Build Add to Cycling Wheel?

What We Tested

In November of 2015, we visited the A2 Wind Tunnel in North Carolina. We tested a FLO DISC in the wind tunnel with the valve cutout covered, and then repeated the test after we removed the covers. Here are a few more details.

1. The same wheel was used for each test.

2. We used a Continental GP 4000 S II tire in a 23mm size for both runs.

Today, tire have changed. If we were recommending tires in 2021, we would recommend the Continental GP 5000. What’s important to note, is that the results from this test will stay very close to the same regardless of tire. This makes the work we did in 2015 relevant today.

How We Tested The Wheels

We like to describe all of the details of our testing so the results are as transparent as they can be. Here is how we tested both wheels at the A2 Wind Tunnel.

1. Tare was calculated and removed from both tests.

2. Each test swept the wheel from 0-20 degrees of yaw, in 2.5 degree increments. The drive side of the wheel was opened to the airflow as the angle increased from 0-20 degrees of yaw.

3. Each measurement was taken twice and averaged.

4. All tires were inflated to 95 psi and calibrated with a digital gauge.

The Results

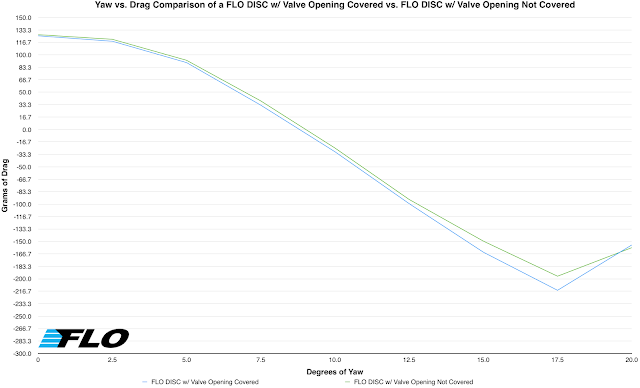

The results were very similar. The Yaw vs. Drag graph below shows the FLO DISC w/ Valve Cutout Covered (in blue) vs. a FLO DISC w/ Valve Cutout Not Covered (in green).

To calculate the time savings for both scenarios, we used our Net Drag Reduction Value formula. This formula was developed using the 110,000 data points we collected while riding a bike with a custom built data logger. The formula uses a baseline wheel, which in this case, was a Mavic Open Pro with 32 round spokes. Please feel free to learn more about our Net Drag Reduction Value formula and Data Logging Process.

In 2015 we only used NDRV. Today we use Net Watt Reduction Value which looks at total power. This includes the aerodynamic drag and rolling resistance produced by a wheel. The reason we are looking at just Net Drag Reduction Value here is because rolling resistance will not be impacted by covering the valve hole, only the aerodynamics. This means we the data is still relevant today.

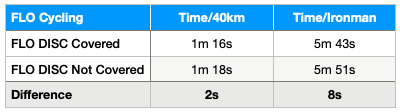

We can see that the difference over a 40km and an Ironman is 2 seconds and 8 seconds respectively. Those difference are pretty small.

Should You Cover The Valve Hole Of A Disc Wheel?

Our recommendation is to cover the valve hole before a race, but if you flat during the race, do not waste the time recovering it.

What Is The Best Way To Cover A Valve Hole On A Disc?

You can purchase special stickers to cover your valve cutout, but our personal favorite solution is using 2″ wide electrical tape. The material is very similar to the covers you can buy, it sticks well to contours, and it’s not impossible to remove. Another benefit is that a roll should last you several years.

Co-founder at FLO Cycling. Jon manages the day to day operations and acts as the lead engineer for all FLO products.