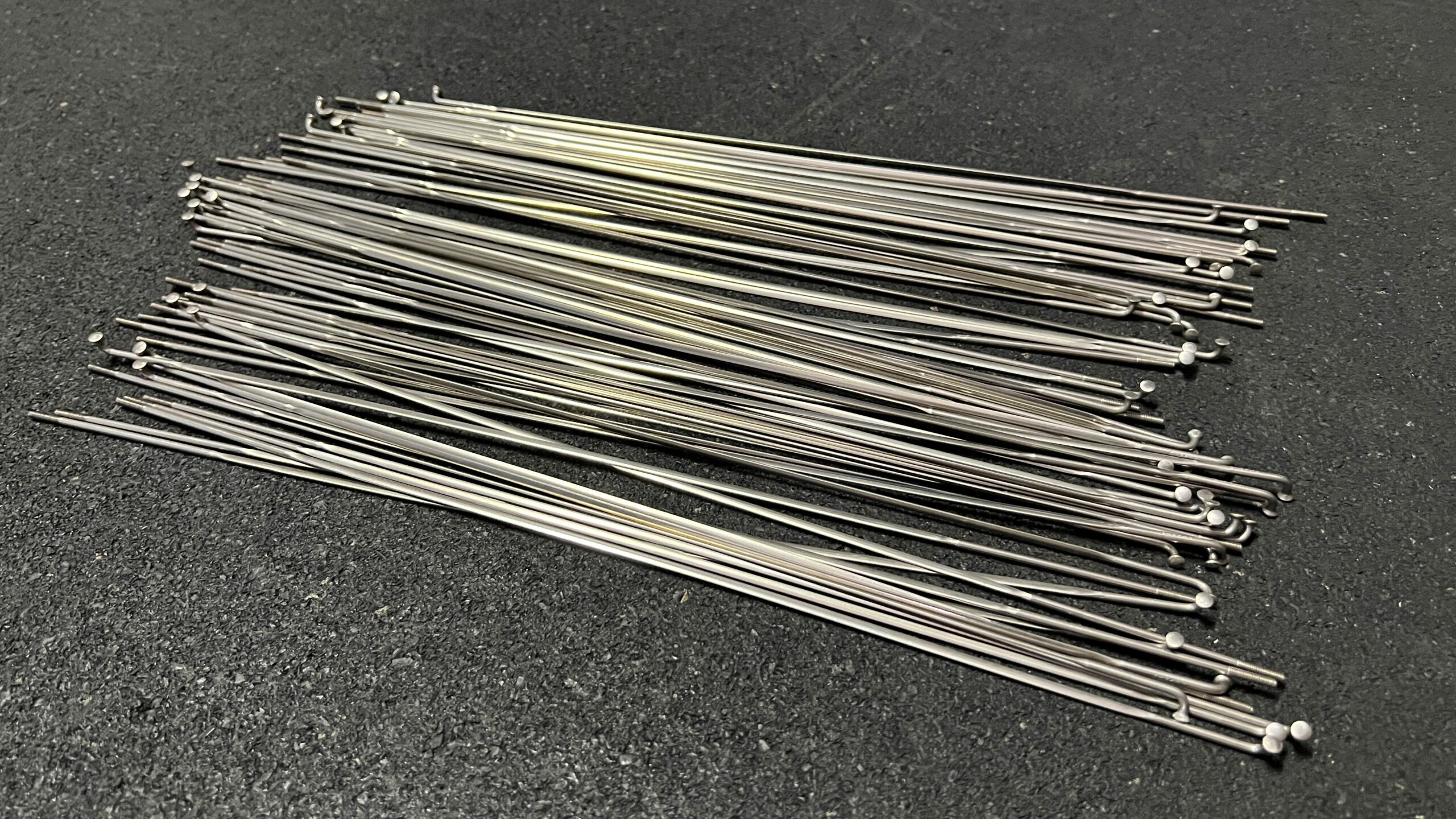

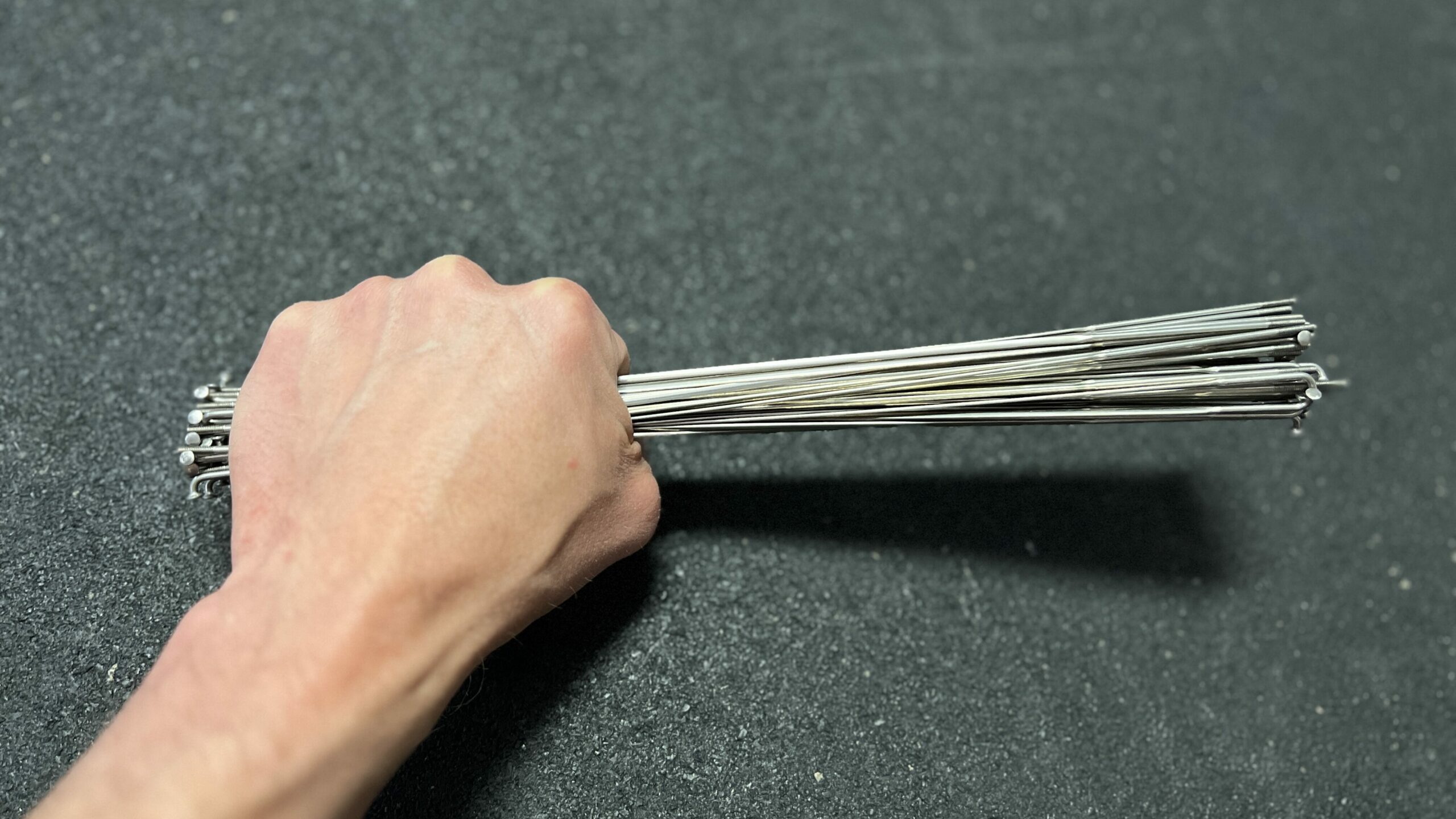

All FLO Wheels (minus the FLO DISC) use Sapim CX-Ray spokes because of their aerodynamic properties. The FLO DISC uses Sapim Laser Spokes since the spokes do not encounter the air.

However, the real magic of a Sapim CX-Ray is its strength and durability which leads to few broken spokes, limited truing, and a long lifetime. You can find spokes cheaper but you’ll quickly find that your wheels will be out of true or you’ll be on the side of the road with a broken spoke. Let’s discuss three engineering concepts that Sapim nailed when designing the CX-Ray.

Elastic and Plastic Deformation

Elastic deformation is the temporary change in shape of a material when a force is applied to it. Think of an elastic band that snaps back into place. When a reasonable force is applied to a bicycle spoke, it undergoes elastic deformation, meaning its shape changes slightly but retains its original shape when the force is removed. This is because the metal that makes up the spoke can flex without breaking, thanks to its elastic properties. A Sapim CX-Ray has incredible elastic properties.

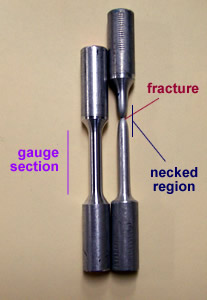

However, if the force applied to the spoke is too great, it can enter the realm of plastic deformation. Think of pulling an elastic so far that it breaks. This is when the material is permanently deformed and does not return to its original shape when the force is removed. In the case of a bicycle spoke, this would mean that it would bend and not spring back to its original shape, causing a weakened spoke and a wheel that is likely out of true. If you were to try and true a spoke that went through plastic deformation, it would likely break or would be out of true very soon afterward.

To prevent plastic deformation in bicycle spokes, it is important to ensure you use proper spoke tensions. If they are too loose, they may undergo plastic deformation due to the repeated bending and flexing that occurs while cycling. On the other hand, if they are overtightened, they may also undergo plastic deformation due to the excessive force being applied to them.

Cheap spokes lack good elastic ranges, will break sooner, and will have you trueing wheels regularly.

Mechanical Fatigue

Mechanical fatigue is another important concept to understand when it comes to bicycle spokes. Mechanical fatigue refers to the gradual weakening and eventual failure of a material due to repeated cyclic loading. Cyclic loading means applying a load and then taking it off. Each cycle represents one loading and unloading. Think of holding an elastic between your hands and stretching it and letting it go repeatedly within its elastic range.

When I studied fatigue at University, I was amazed to learn that most items are designed to fail after a certain number of cycles. For example, the axle of a car is designed to fail after a certain number of revolutions. Fatigue will eventually lead to the failure of a material.

In the case of bicycle spokes, fatigue occurs each time the wheel rotates, the spokes are alternately compressed and stretched, causing small amounts of damage to accumulate over time. This will eventually lead to the spoke breaking. Sapim CX-Rays can handle an extremely high number of cycles before breaking. Most spokes don’t even come close and break much sooner.

Mechanical Creep

Mechanical creep is a phenomenon that occurs in materials under constant stress over time. It is the gradual deformation and elongation of a material due to the application of a constant load or stress. Think of holding an elastic in a stretched state for a long time. Eventually, it is longer when released.

In the case of bicycle spokes, mechanical creep can occur due to the constant load that the spokes experience while supporting the weight of the rider and the bicycle. However, since bicycle spokes are typically made of high-strength materials such as stainless steel or high-tensile steel, they are less susceptible to mechanical creep than other materials that are more prone to creep, such as plastics or soft metals like aluminum.

That being said, mechanical creep can still occur in bicycle spokes if they are subjected to very high loads or stress over a prolonged period of time or are made from poor materials. For example, if a rider is significantly heavier than the weight the wheel build was designed to support, or if the spokes are repeatedly overloaded, they may eventually undergo creep and elongate over time. Spaim CX-Rays have a very low potential to creep especially when build properly.

Final Thoughts

If you’ve ever bought a bike with OEM wheels or subpar spokes, you will likely notice that the spoke count of the wheels is higher. This is for two reasons:

- The spokes are generally cheap and use poor materials so more spokes are needed to account for the poor spoke.

- The builder has no idea who will ride the wheel. Will they weigh 120 lbs or 300 lbs?

As a result, you get overbuilt wheels, need constant truing, and find yourself replacing broken spokes. Preventing plastic deformation, fatigue, and creep keeps your wheels true and your spokes intact. This makes you faster and prevents issues you don’t want to deal with. While CX-Rays are costly to FLO as a brand, they are worth every penny in the long run.

Co-founder at FLO Cycling. Jon manages the day to day operations and acts as the lead engineer for all FLO products.