Tubeless is becoming more and more popular these days. The set up can be a little intimidating but once you get it, it’s great! (Have you signed up for our tubeless guide? If not, do so here) However, I felt the need to address one of the set up options and why it’s not recommend for FLO wheels- and that is using a compressor.

At FLO, we strongly advise against using a compressor for inflating tubeless tires. Using a compressor to inflate tubeless tires can result in a wheel that is damaged beyond repair. We recently had a customer destroy their wheels because the tape was not properly installed. Unfortunately, this is not covered under warranty (you know us, we will always help out). Let’s walk through why your rim can explode in the first place and what our recommendations are for inflating tubeless tires.

The History Of Using A Compressor With Tubeless Tires

The original tubeless tires were installed on traditional rims. By traditional rim, I mean an internal rim structure that was designed for tubes which made tubeless installation difficult.

When you’re installing a tire with a tube, you do not need to worry about creating a tight seal so the air does not escape. As you inflate the tire, the already sealed tube pushes the tire into the hooks of the rim.

For tubeless, you need to worry because until the bead of your tire creates a tight enough seal with the rim, air escapes from underneath the tire.

To help solve this problem, compressors were used to give a high pressured quick blast of air to try and quickly seat the tire on the rim.

The Potential Problem With Using A Compressor

In theory, a compressor is not problematic for tubeless tire installations. The deciding factors are the installation of the tubeless rim tape and how the rim is made.

As previously mentioned, when tubeless rim tape is properly installed, you create a completely sealed rim cavity. This means the spoke holes and valve stem openings will not allow any air to enter them. If the rim is not properly sealed, then air can enter the rim cavity.

The original tubeless rims were made from aluminum so having air enter the spoke hole or valve stem was more of a nuisance than a potential problem. An aluminum rim is an extruded piece of metal and can withstand the normal forces that a rim experiences and can also withstand an inflation pressure from inside the rim cavity if air enters.

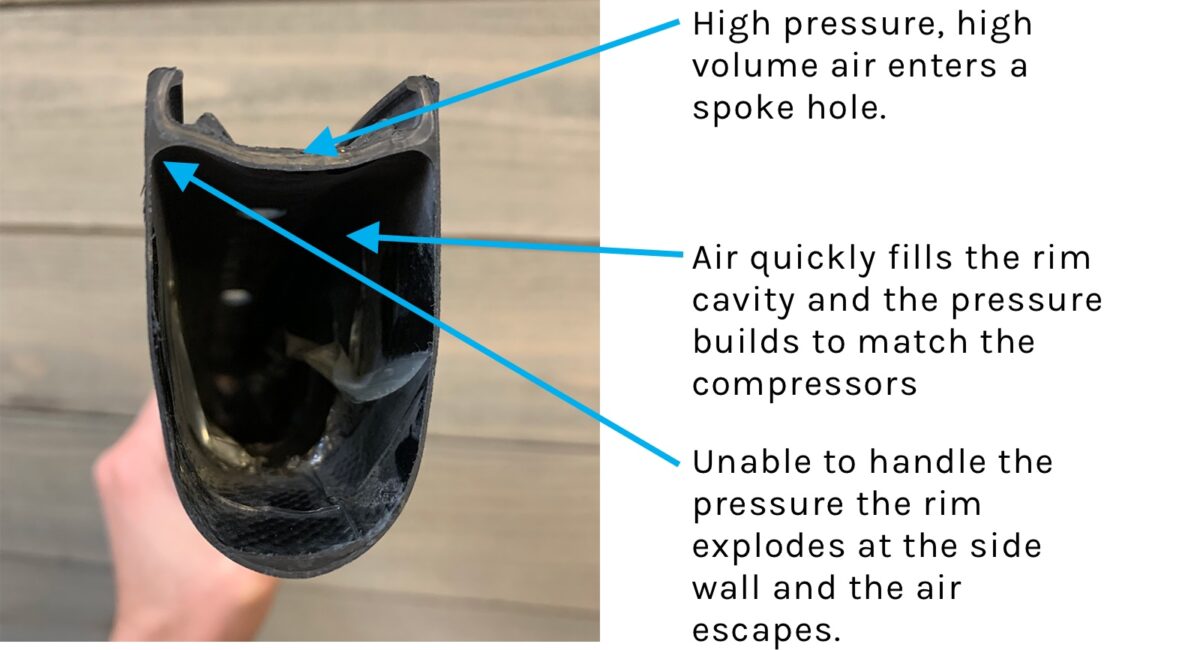

For carbon rims this is much different. Carbon rims are made by laying up carbon fiber. The fiber layup design does not consider an inflation pressure from inside the rim cavity. Therefore, if air enters the rim cavity with high volume and high pressure it will find the path of least resistance when it decides to leave the rim. This usually results in the side wall of the rim splitting apart from the rim bed destroying the rim. The image below explains the process.

To show you what this looks like, the image below shows a customers rim that experienced this problem. You can see the crack in the rim due to improperly installed rim tape and the use of a compressor.

Compressors vs. Floor Pumps For Tubeless Tires

So why would a compressor be a problem and a floor pump not be a problem if you are inflating to the same pressure? Even if the compressor was set to the recommended tire pressure, you can still experience damage. A compressor is different than a pump because of the volume of air.

Let’s assume that the rim tape is improperly installed and air is able to enter the rim cavity. When you use a compressor, a large volume of air enters the rim cavity. As the volume increases, so does the pressure. There are small voids around the spokes and valve but the volume of air rushing into the rim is far greater than the amount of air that is allowed to leave the rim cavity and as a result the pressure builds to the point where the rim pops to allow the air to escape.

When using a floor pump, the volume of air is slow and controlled. If you have improperly installed rim tape the air still enters the rim cavity it just has time to escape around the spokes and valve. In this situation the volume entering the rim cavity is less than the amount that is able to leave so the pressure does not build. So, even if you did not install your rim tape properly you’ve spared your rim.

Now assuming you got a good seal on your rim tape, the compressor can work very well. However, so does a floor pump.

New Tubeless Ready Rim Design

In the beginning of this article, we discussed how the original tubeless tires were installed on traditional rims. Today, we have rims that work well with tubeless tires. As a result, you do not need to hook up your compressor, blast the tire with air and cross your fingers hoping the tire seats.

Our Tubeless Tire Installation Guide

If you are interested in installing tubeless tires, we recommend you check out our guide “The Ultimate Guide To Installing Tubeless Tires.” It’s a four part video series that walks you through all of the steps to successfully and safely install tubeless tires.

Our Thoughts On Road Tubeless

Simply stated, we absolutely love tubeless! Shortly after our first tubeless install it was really difficult to find a reason why we would use tubes again. If your wanting to give tubeless a shot and have questions, please feel free to reach out on our contact page. Just remember, please don’t use a compressor. Have fun and ride safe!

Co-founder at FLO Cycling. Jon manages the day to day operations and acts as the lead engineer for all FLO products.