Legacy Article: The data discussed in this article is taken from our previous generation of wheels.

Article Quicklinks

hide

Introduction

When we set out on our journey to design aerodynamic cycling wheels, we asked ourselves, “what makes a wheel aerodynamic?” We soon learned there wasn’t a real answer. After hours of research, computational fluid dynamics testing, and a trip to the A2 wind tunnel, we now know what makes a cycling wheel aerodynamic. Below are several paragraphs discussing how we designed our FLO Cycling wheels and of course our wind tunnel results. For those who are interested in understanding the science that goes into designing aero wheels, we have added an additional section to the end of this blog post titled “Aero Wheel Tutorial.“ As always, questions and comments are more than welcome!

Be sure to check out our latest wind tunnel results on the all new FLO wheels. You may also find Part 1 and Part 2 our tire study of interest. In our tire study, we studied the combined resistance of aerodynamics and rolling resistance on nearly 20 tires.

Be sure to check out our latest wind tunnel results on the all new FLO wheels. You may also find Part 1 and Part 2 our tire study of interest. In our tire study, we studied the combined resistance of aerodynamics and rolling resistance on nearly 20 tires.

FLO Cycling Design

The picture below shows the progression of aerodynamic wheel shapes. The V-Notch design was one of the earliest aerodynamic wheel shapes on the market. This wheel displayed a reduction in aerodynamic drag but is known for being unstable in crosswinds. Many manufacturers still use this technology today.

Designers next released what was known as a toroidal shape. The toroidal fairing flared out and got wider than the brake track before coming to a point. This design showed an even greater reduction in aerodynamic drag and improved crosswind stability

FLO Cycling Symmetrical Design

In our opinion, the largest downside to both the V-Notch and early toroidal design is that they come to a point. The leading edge on the front half of any wheel is the tire. A tire is a bulbous circular object. If we want to create even side force on the front half and the back half of the wheel, we assumed that the leading edge on the back half of the wheel would have to also be a bulbous circular object. By removing the “point,” we have been able to create a balanced aerodynamic system. On a FLO Cycling wheel, the leading edge on the front half of the wheel (the tire) is nearly identical to the leading edge on the back half of the wheel (our wide toroidal shape). This design reduces the aerodynamic drag even more than the early toroidal shapes and greatly improves crosswind stability. FLO Cycling wheels are nearly symmetrical from front to back. The result of this symmetry is superb aerodynamics and superior crosswind stability.

>Net Low Drag Technology

When we sat down to design our wheels we observed the aero data published by other companies and noticed a trend. Their wheels became very aerodynamic at a specific yaw angle. Unfortunately, a few degrees in either direction of that yaw angle caused the drag to rise quickly. This produces good results in a controlled environment like a wind tunnel, but doesn’t necessarily help in the real world. We’d all love to ride our next race at the optimal wind angle, but mother nature simply won’t let that happen.

Our goal was to produce wheels that became aerodynamic and stayed aerodynamic for as long as possible. We knew that roughly 80% of a cyclist’s time is spent riding in yaw angles between 10 and 20 degrees. During our CFD analysis we tweaked our wheel shapes to be as aerodynamic as possible throughout that 10 degree sweet spot, and not at a specific point. The wind tunnel results were remarkable. As an example, our FLO DISC wheel experiences negative drag from 12 to 24 degrees of yaw.

A lot of companies claim to have the fastest wheels in the world. At specific angles, using specific tires, and in a wind tunnel, they certainly do. They also say that at that specific angle the wheel will save you X amount of seconds at your next race. Unfortunately, the wind will not be blowing only at 12.6 degrees of yaw at your next race.

At FLO Cycling we wanted to define a useful term. Since we know we spend roughly 80% of our time racing between 10 and 20 degrees of yaw, we feel it is best to calculate a weighted average of drag reduction. A cyclist would then have an excellent idea of how many seconds a FLO Wheel will save them regardless of the wind angle. We call this value the Net Drag Reduction Value (NDRV).

Below are the NDRV of our FLO wheels and the optimal reduction value assuming mother nature is only blowing at the perfect angle all day. These values are the amount of grams saved when compared to a standard box section rim (Mavic Open Pro – 32 Spokes).

FLO CLIMBER

NDRV: 78.3 grams – 31.3 seconds over a 40km time trial OR 2 minutes and 21 seconds over an Ironman.

Optimal Reduction: 88.3 grams – 35.3 seconds over a 40km time trial OR 2 minutes and 39 seconds over an Ironman.

FLO 60

NDRV: 175.3 grams – 70.1 seconds over a 40km time trial OR 5 minutes and 16 seconds over an Ironman.

Optimal Reduction: 210.1 grams – 84.0 seconds over a 40km time trial OR 6 minutes and 18 seconds over an Ironman.

FLO 90

NDRV: 172.1 grams – 68.8 seconds over a 40km time trial OR 5 minutes and 10 seconds over an Ironman.

Optimal Reduction: 202.1 grams – 80.9 seconds over a 40km time trial OR 6 minutes and 04 seconds over an Ironman.

FLO DISC

NDRV: 253.7 grams – 101.5 seconds over a 40km time trial OR 7 minutes and 37 seconds over an Ironman.

Optimal Reduction: 319.9 grams – 128.0 seconds over a 40km time trial OR 9 minutes and 36 seconds over an Ironman

Without further ado, here are the FLO Cycling Wind Tunnel Results…

Aero Wheel Tutorial

Let’s start by defining some terms:

Yaw Angle

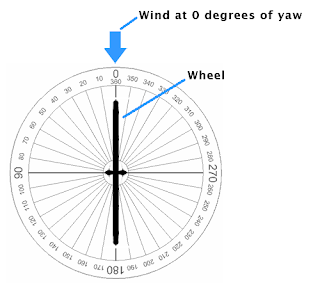

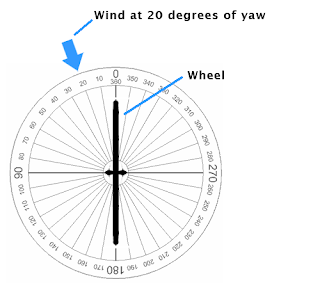

A yaw angle is the angle at which the wind interacts with the wheel. Take a look at the pictures below. In Figure A, the wind (blue arrow) is hitting the wheel at 0 degrees. This is known as 0 degrees of yaw, and what you experience when the wind is blowing straight at you. In Figure B, the wind is now interacting with the wheel at a 20 degree angle. This is known as 20 degrees of yaw and the cyclist would a feel a combination of headwind and side wind.

Let’s start with a visual. Imagine a canoe moving through a calm lake. The front of the canoe is the first part of the boat to cut through the water. It is therefore defined as the “leading edge.” A wheel in the wind is no different. Remember, air is a fluid just like water.

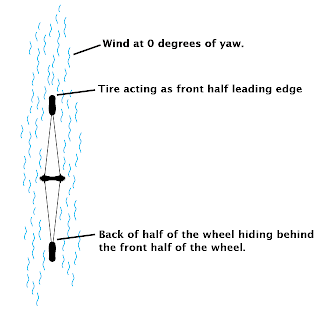

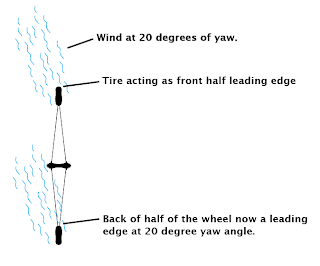

A wheel can have two leading edges. The tire at the front of the wheel, and the carbon fiber fairing at the back of the wheel. When a wheel is at 0 degrees of yaw, the front of the wheel is the only leading edge. This is because the back of the wheel is “hiding” behind the front of the wheel (see Figure C). When a yaw angle of greater than 0 degrees is introduced, we now have two leading edges. Figure D shows the wind at 20 degrees of yaw. The back of the wheel can no longer “hide” behind the front of the wheel and sees its own air. It is therefore defined as a leading edge.

|

| Figure C |

|

| Figure D |

Drag |

Drag is defined as the force on an object that resists its motion through a fluid. Let’s use another water example. If you stand in waist deep water and try to run forward, the force you feel holding you back is drag. Air also has drag, just not as much as water.

Co-founder at FLO Cycling. Jon manages the day to day operations and acts as the lead engineer for all FLO products.