Last week I wrote a blog article that discussed why you reduce the air pressure in a tire when you widen the wheel or increase the tire size. While writing the article, I started thinking about how a tire supports its load. My first guess was the air pressure, but that’s incorrect. It plays a role in the equation, but there is another part of the story.

If you haven’t read last week’s article, “Why Do You Use Less Tire Pressure for a Bigger Tire or Wider Wheel?” I suggest you do. It will likely provide some background that will help with this article.

Tire Pressure, What Does it Do?

When you pump up a tire, you increase the air pressure. My first thought was that by increasing the air pressure, the tire would support its load. The load exerted from the road to the tire would be opposed by the tire pressure pushing down on the road. However this is not the case.

The purpose of the air pressure in the tire is to hold the tire casing under tension. As we increase the tire pressure, the threads of the casing are placed under more tension.

How A Tire Supports Its Load, The Basic Explanation

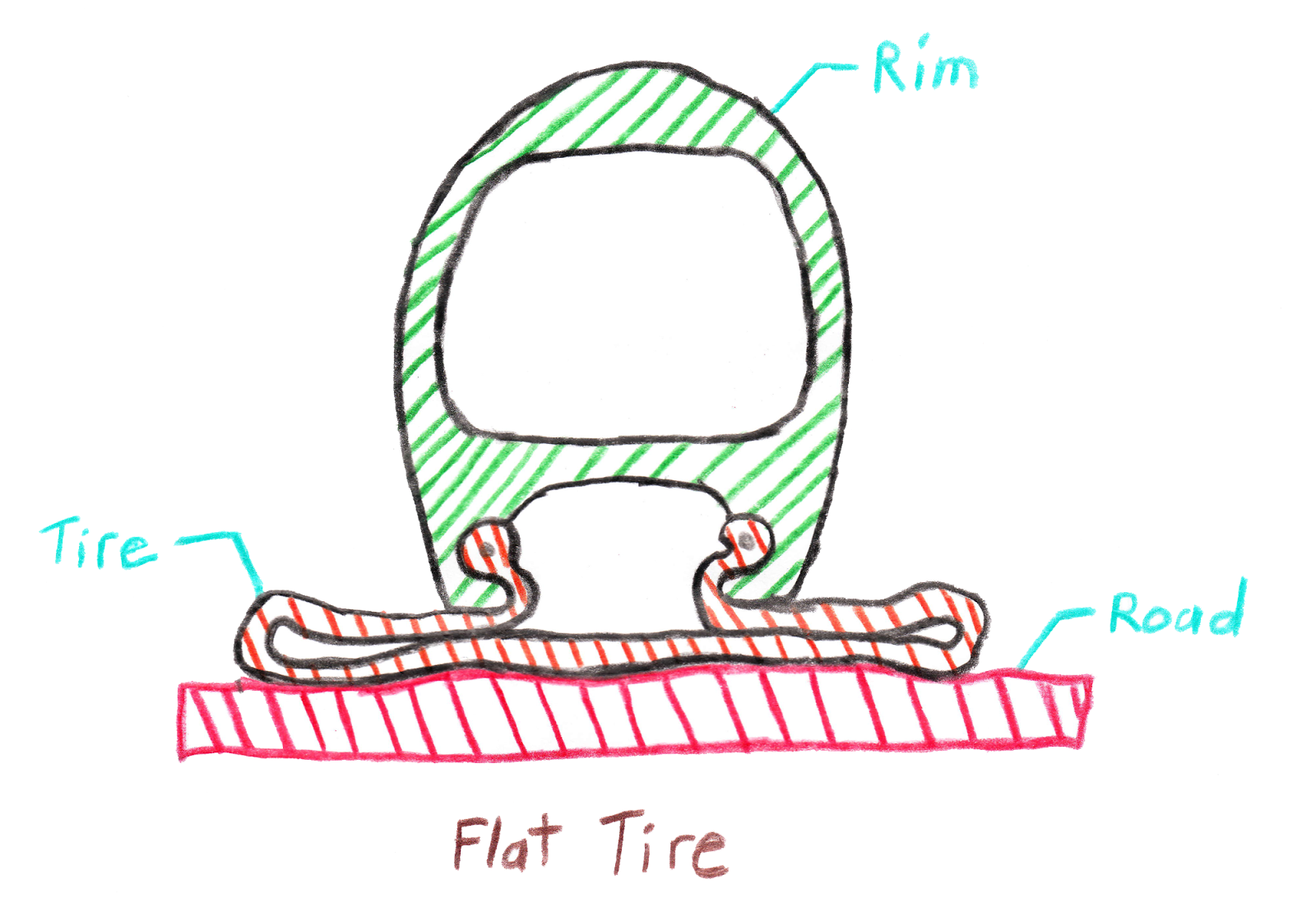

As stated above, the purpose of tire pressure is to increase casing tension so the tire can support itself. If you have a flat tire, there is no casing tension and the sidewall cannot support the load placed on the wheel. The picture below shows a cross-section view of a flat tire. The sidewalls of the tire are folded and the rim makes contact with the ground. Flat means there is no air, the casing tension is too low, and the sidewalls cannot support the load.

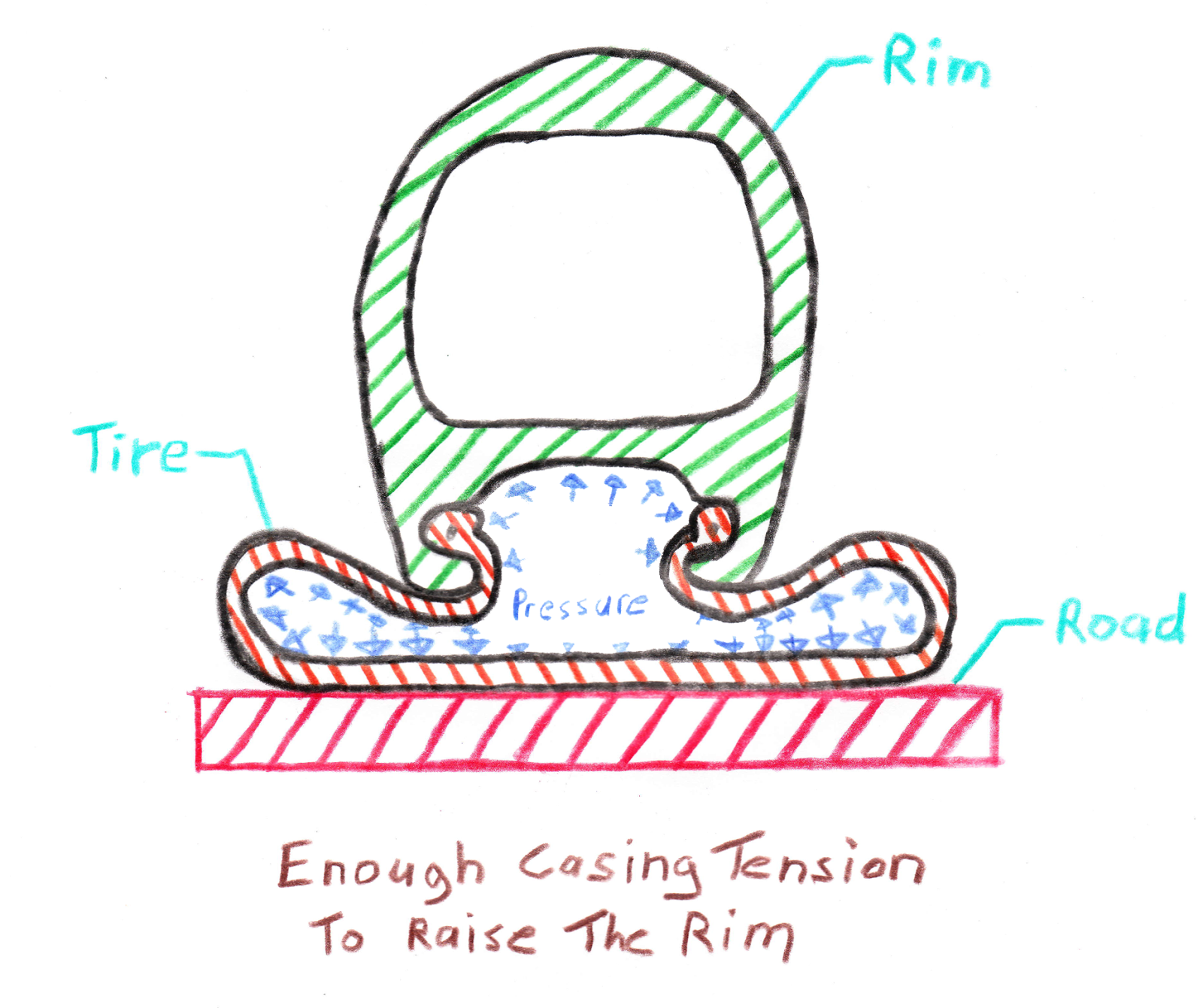

As we increase the air pressure in the tire we also increase the casing tension of the tire. At some point the rim will leave the ground and the sidewall will have enough casing tension to support the load on the wheel.

How A Tire Supports Its Load, The More Complicated Explanation

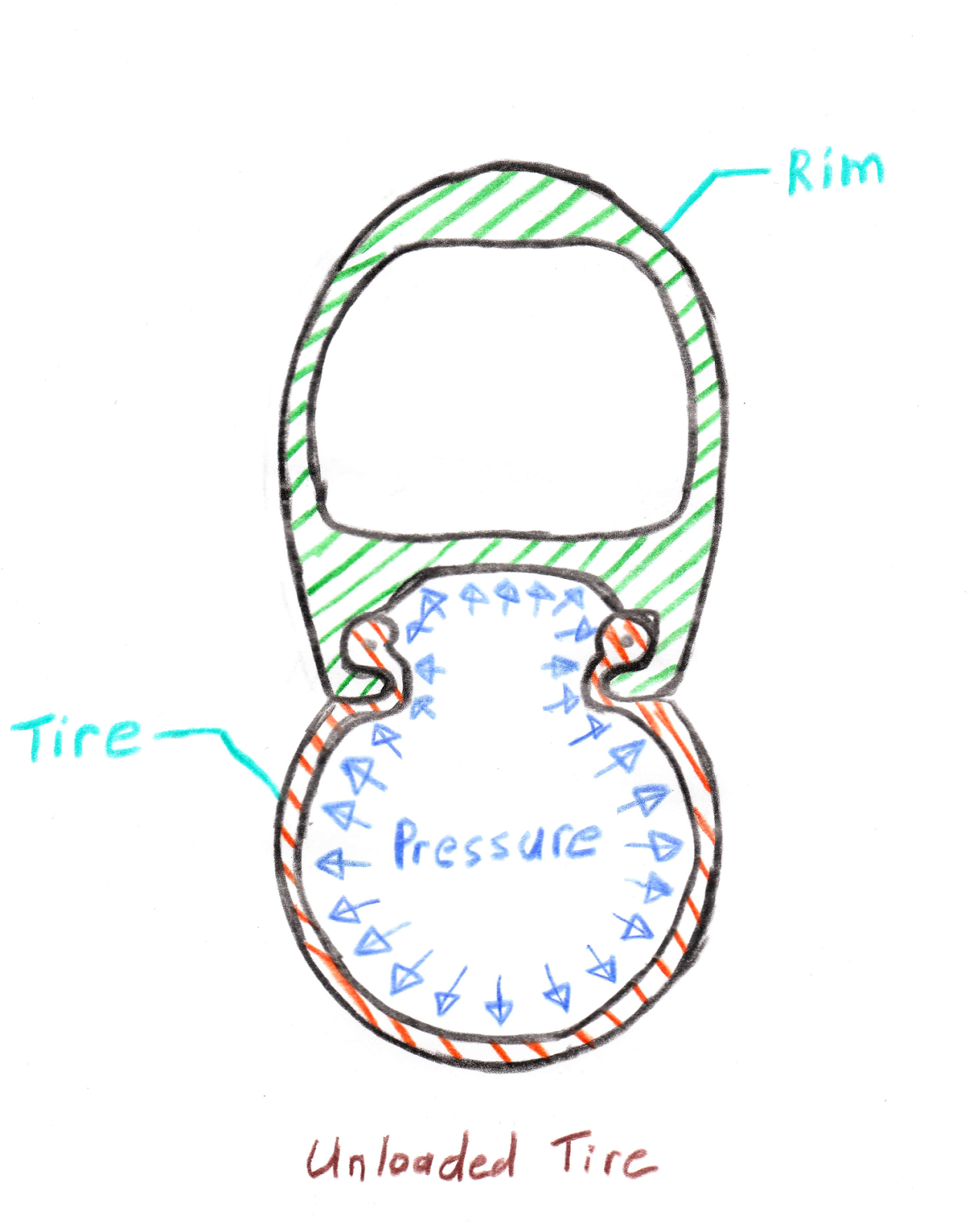

A tire that is in an unloaded state can be seen in the picture below.

You can see that the force arrows created by the internal pressure act perpendicular to the internal tire surface. In this example, all of the threads in the tire casing experience the same tension.

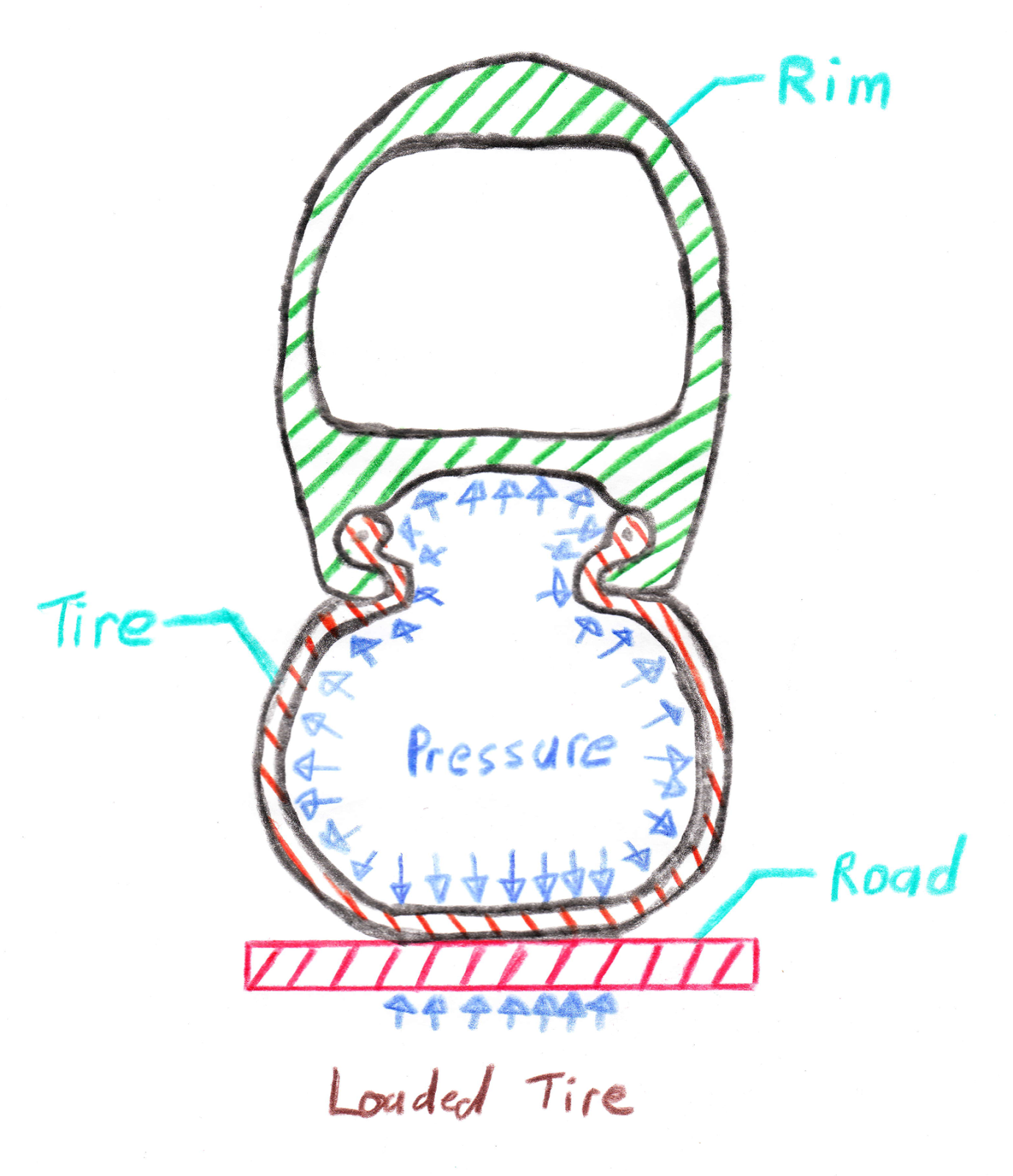

When a tire is loaded, there is a flat section that makes contact with the road, which is known as the contact patch. This flat section changes the circular shape of the tire. The section of casing that is the contact patch experiences a reduced or eliminate casing tension. This means the threads next to the contact patch (the sidewalls) have to increase their casing tension to make up for the reduction in casing tension experienced by the contact patch. When a tire is loaded you will see a bulge on the sides of the contact patch. This bulge is created by the increased casing tension in this section. The video above gives a visual explanation of this.

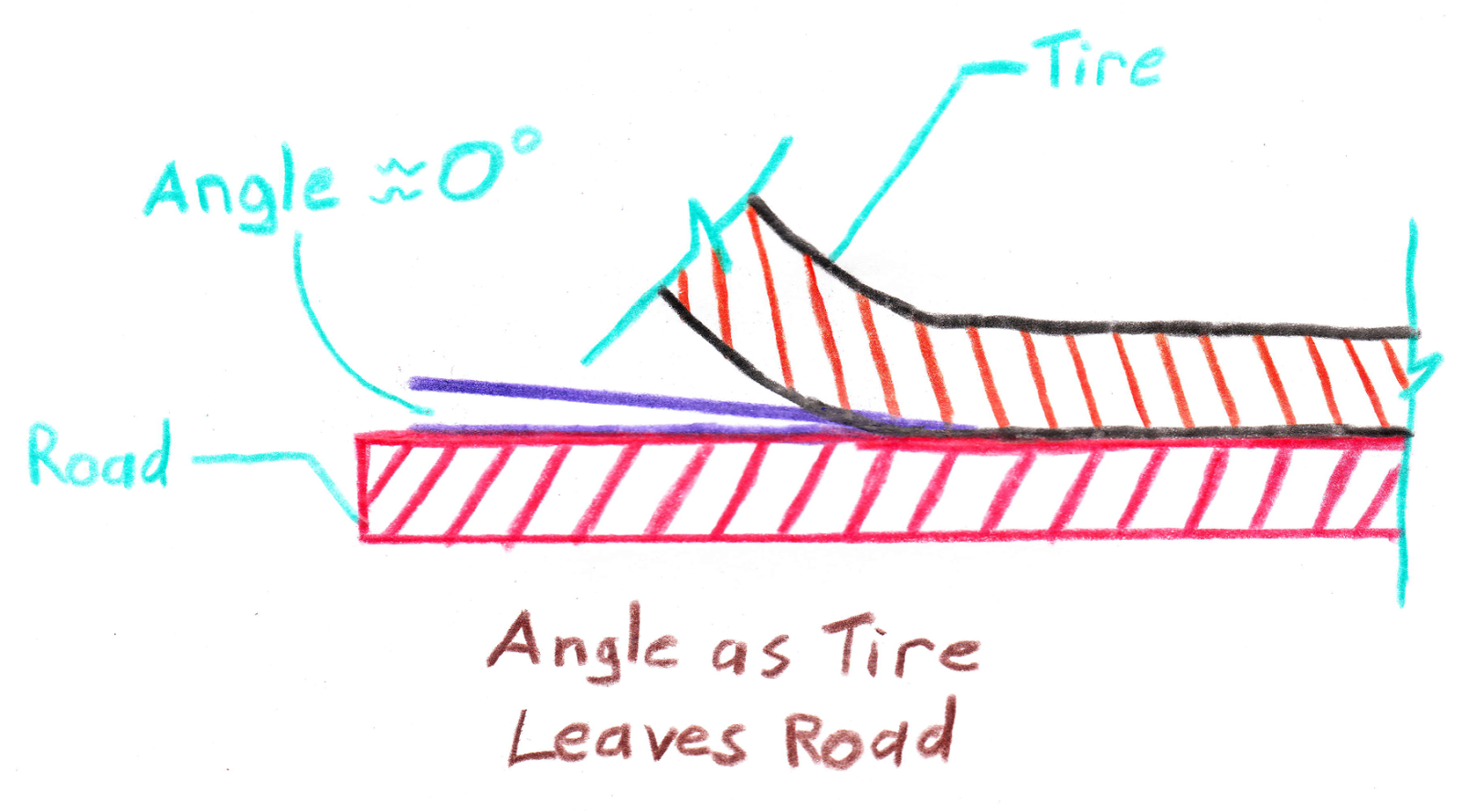

Where the unloaded tire has a uniform circular shape, the loaded tire does not. As the tire leaves the ground and makes its way towards the rim, the angle of the tire is very close to zero. The picture below shows what I mean.

Since the angle of the threads next to the contact patch are close to zero, most of the force (load) is transferred horizontally and eventually makes its up to the side wall. The increased tire pressure allows the casing and side wall of the tire to support the load placed on the wheel. Without the proper tire pressure and resulting casing tension, the tire could not support its load.

That sums up today’s article. I hope it made sense. Please let me know if you have any questions or comments.

Take care,

Jon

Co-founder at FLO Cycling. Jon manages the day to day operations and acts as the lead engineer for all FLO products.