The goal of a wheel designer is to create the fastest wheel possible while also reducing drag as much as possible. When the design of the FLO 30 was underway, I was asked a really great question recently that I thought deserved some attention.

Does CFD and time in the wind tunnel really help you design better wheels or is it just an advertising gimmick?

The answer is a simple one but I thought it deserved some explanation. The point of this article is to:

- Explain how and why CFD and wind tunnels are used to produce better products.

- Explain how CFD and wind tunnels can be used as marketing gimmicks.

- Explain how to identify when CFD and wind tunnels are being used for design or marketing.

Background on CFD and Wind Tunnels

CFD and wind tunnels have been around for many years. They were developed to be used as engineering tools to aid in the design of products. They are used to study the flow characteristic around bodies immersed in a fluid. In their early years, like most technologies, they were extremely expensive and required robust systems to be operated. Over the last few years, CFD software and wind tunnel testing have become much more affordable and are now within the reach of many companies or individuals. This is no different then a technology like Blu-Ray and VHS.

Just like any technology, when the prices drop, there are new opportunities for companies to use them to design better products. Unfortunately, there are also companies who use these technologies as marketing gimmicks. It is important to understand that there are two options for people that start a cycling wheel company. The first is to design a wheel and open proprietary molds to create the products. This includes drafting shapes, testing the shapes in CFD and/or a wind tunnel, modifying the shapes, and repeating to find the fastest wheel shapes possible before creating a mold. This option is time consuming, takes a level of expertise, and costs a considerable amount of money.

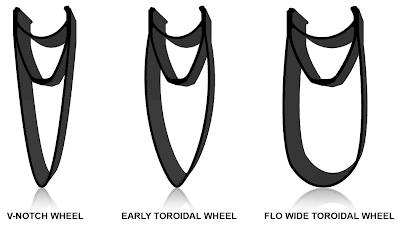

The second option is to use open molds. Open molds are molds that are owned by factories. Companies can visit a factory, look at a show room full of products and say “we would like to to buy 1,000 of those and please put our logo on them.” This approach takes less time and is more cost effective. The problem is that open molds are based on old technology. We know today that the wheels produced from open molds are not as aerodynamic when compared to the more modern designs. The shapes of these wheels are often titled V-Notch, Hybrid Toroidal, and Advanced Profiles, among others.

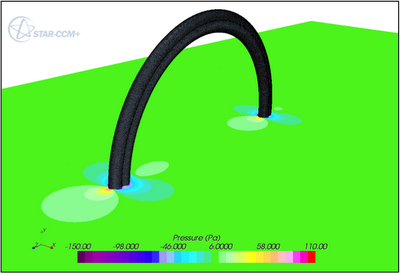

How and Why CFD and Wind Tunnels are used for Design

Most people buy race wheels for one reason: to go faster. The single largest factor that will increase the speed of a cyclist is to reduce drag. For companies that design wheels, this is the main reason for using CFD and wind tunnel testing.

CFD and wind tunnels have to be a forethought if you are going to use them for design. To use them as legitimate design tools, they must be used prior to opening a mold. CFD and wind tunnels allow a designer to test a number of shapes, tweak designs, and learn what produces the best results. Once you are satisfied with the results, you send drawings to a mold maker who creates a set of custom molds. In a nutshell, CFD and wind tunnels are part of the design process when they are used to refine a rim shape for optimal aerodynamics before a mold is opened.

How CFD is used for Marketing

So how would someone use CFD and wind tunnel time as a marketing gimmick? Though CFD and wind tunnels are many years old, they are relatively new to the cycling world. The industry pioneers were able to produce great products when incorporating these tools into their design process. Like any industry, when someone does something new, the competition takes note. The recognition gained by those who pioneer the way creates a reaction in one of two ways. Companies use this same technology to create better products for themselves or they find a way to use these new “buzz words” in their advertising campaigns.

Let’s assume that someone uses an open mold rim (non proprietary design/ has not designed the product themselves) or has an existing line of products that they currently sell which they did not use CFD or wind tunnels to design. If CFD and wind tunnels are design tools, then why would people use them for products that have already been designed? When CFD and wind tunnels are an afterthought they can do nothing to improve the design of a product. This leaves one reason to use CFD and wind tunnels for a product that is already designed. You guessed it, marketing. If design companies are generating a buzz by actually using a technology to create a better product, then other companies are sure to try and take advantage of this new opportunity. If they run a CFD simulation or spend time in the wind tunnel with their existing products, it’s a deceiving way to make someone believe the tools were used to design better products. Simply showing fancy CFD images or shooting a picture of wheel in a wind tunnel does not mean the product was designed with those tools. This is how CFD and wind tunnel time are used as marketing gimmicks.

How to Identify when CFD and Wind Tunnels are used for Design or Marketing

There are telltale signs for those wanting to know what a company’s intent is.

Signs that CFD and wind tunnel time have been used for design include the following:

- Extensive study is done before a mold is opened. This is normally discussed and shown during development or at the time when the product is released.

- The company owns proprietary molds.

- The company openly publishes wind tunnel data and testing protocols. This includes drag data at specific yaw angles that is most commonly shown in a drag vs. yaw graph.

- They do not use blanket or cliche statements about how fast a product is without supporting information.

Signs the CFD and wind tunnel time are used for marketing include the following:

- There is no proof that extensive study went into designing a product. Statements that claim a company is an engineering company is one thing. Providing data to prove you are an engineering company is another. If you did design a product naturally you want to let people know. Watch out for statements not backed up by data.

- The company does not own proprietary molds. They may own molds to guarantee their production quantities, but anyone with the money can buy the same mold. Make sure you understand the difference between owning a proprietary mold and owning a mold.

- The company does not publish wind tunnel data. Most often this is not done because the data shows the wheels are inferior to proprietary designs.

- The company uses blanket statements to make the products sound better. These include things like:

“Of all the designs we’ve tested, our shape is the fastest.”

This could mean they only tested two shapes. If you see something like this look at the wind tunnel data if it exists.

“We are continually refining our products to bring you the best technologies.”

This works if there is legitimate data to support the claim. If the data is missing, keep an open mind for what this really means.

5. The company uses a v-notch profile or a modified toroidal shape.

Final Thoughts

The biggest thing to look for when deciding why CFD and wind tunnels are used is the transparency of the company. If the company shares the design process and publishes the data, you are most likely looking at a company who designs wheels. If the company makes blanket statements, uses v-notch shapes or publishes data without a supporting design process, you are most likely looking at a company using CFD and wind tunnels as marketing gimmicks.

In the end, I’d like to clarify that the companies who use CFD or wind tunnels for marketing are not bad companies. This also does not mean they have bad products. It simply means that CFD or wind tunnels were not used by them to design a better product. If your goal is to go faster when you purchase a set of race wheels, make sure you look for the important details. Transparency is key.

Co-founder at FLO Cycling. Jon manages the day to day operations and acts as the lead engineer for all FLO products.